Designing with HSS: ERW Manufacturing Process

Hollow structural sections are used as a structural element in buildings, bridges and other structures, and in a wide variety of manufactured products. It’s produced in round, square and rectangular shapes in a broad range of sizes and gauges.

Watch the fifth installment of the Designing with HSS video series and learn about the production values and process of HSS.

Atlas Tube’s ERW manufacturing process delivers superior quality and speed that is unmatched by our competitors. Our mill operators have the experience and “know how” to deliver your project on time. Atlas’ facilities operate two shifts daily, which allows us to produce up to 2,400 tons of prime product per day.

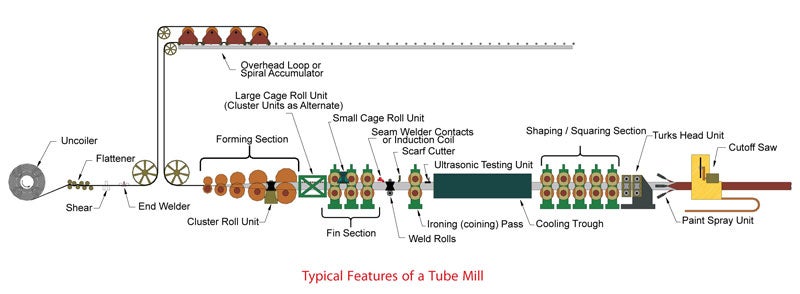

The picture above illustrates the typical features of a tube mill and the level of equipment needed to accomplish the basic task of producing tube. The entry section of a tube mill will feature some means to unroll the strip from its coil form, and a way to join the end of the last coil to the beginning of the next. All tube mills will feature a series of tooling to form the strip into tube and a welding station to join the seam of the tube, followed by some method for cutting the tube to length. Some mills feature additional equipment to make the operation more efficient, or to add special features to the tube. The headings that follow identify the equipment common to most tube mills, as well as some of the specialty equipment that may also be featured on a particular mill.

If you have any ideas for additional topics, or questions about any of the information provided in the series, please let me know at brad.fletcher@atlastube.com