Better Bolted Connections

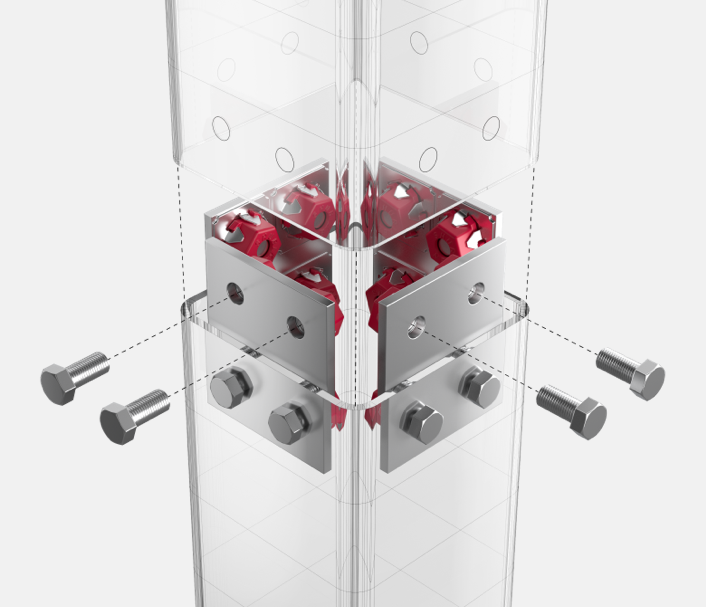

Quickly and easily field bolt what you once had to weld with a built-in wrench that goes where your hands can’t.

Spark your imagination with conceptual details and sample configurations for field-bolted connections with Shuriken.

HSS offer high strength-to-weight ratios, exceptional torsional resistance, and an aesthetically pleasing appearance, but complicated connections and welds have traditionally been drawbacks. Not anymore. Shuriken allows you to skip the complicated connections and field bolt columns, trusses and beams.

See how Shuriken and Jumbo HSS played a vital role in the North Post Oak Road Pedestrian Bridge.

Learn moreWhen engineers were designing a steel bridge over a busy railway, Atlas Tube’s Jumbo HSS and Shuriken® Structural Nut Keeper were the right choices to support a highly ambitious design.

Learn moreIf you’d like a sample or want to learn more about how Shuriken can help you find big efficiencies and open up new possibilities on your next steel construction project, get in touch with one of our steel engineers.

Learn how Shuriken makes bolted field splices simple, fast and affordable.

View literatureSee what's available from Atlas Tube's mills.

View chartFind out more about what sets Atlas Tube Jumbo HSS apart.

View literature