When fabricators needed to move 66-foot braces to a project supporting international shipping traffic, Atlas Tube’s domestic Jumbo HSS and Shuriken® Structural Nut Keeper made transportation and procurement easy for these crucial bridge supports.

Established in 1926, the Port of Corpus Christi has evolved over the past 100 years to become the United States’ largest energy-exporting port and the third-oldest oil exporting port in the world. With connections to three major railroads, two major highways, and direct access to the Gulf of Mexico, the port is an integral part of the local economy and global trade.

In 2003, the Texas Department of Transportation determined that the existing Harbor Bridge needed to be replaced. The old Harbor Bridge suffers from safety concerns, including a lack of shoulders, a steep grade, no foot or bicycle access, and extremely low clearance for ships passing beneath it. The new Harbor Bridge aims to increase safety for motorists, cyclists, and pedestrians alike while expanding commercial access for maritime vessels of all shapes and sizes.

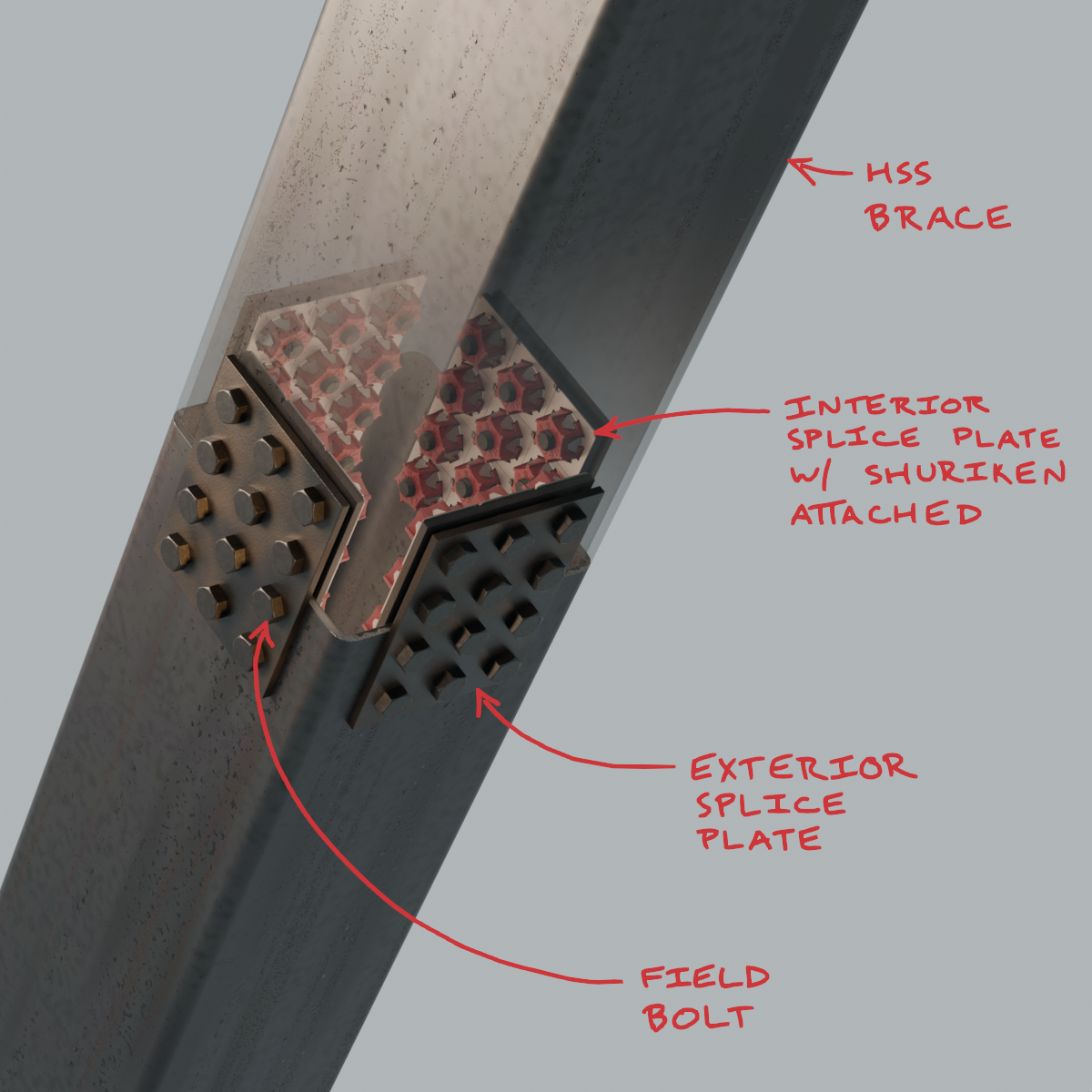

The new bridge’s cable-stayed design meant that temporary supports were required to maintain stability until the two halves of the main span were connected over the shipping channel. At ~150’ tall, the temporary supports were large structures unto themselves, and included 66’ long, 18” square Jumbo HSS braces. The supports’ fabricator, ATS Industrial, faced the challenge of procuring, fabricating and shipping those braces as efficiently as possible. “This project was schedule driven. [If we didn’t include field-splices] we would have had to ship 66’ pieces, which would have been an oversized load,” says Brett Lee, CEO of ATS Industrial.

ATS opted to use Atlas Tube’s Shuriken Structural Nut Keeper, which allows one-sided connections using standard high-strength bolts. Thanks to Shuriken, ATS was able to purchase standard lengths of HSS from their local distributor, Delta Steel, and field bolt the supports on-site. This saved ATS time and money on procurement, logistics, and fabrication. “I was able to save money by buying in-stock material instead of mill-run material,” says Lee. By purchasing standard lengths, ATS cut lead time by several weeks and was able to transport the braces to the site without the need for an oversized load designation, reducing freight costs.

Although Shuriken is not the only way to make a bolted HSS splice, Lee found it to be the most efficient option after examining the alternatives. The initial splice design was an end plate joint. But the 2” thick end plates represented a significant material cost, and drilling holes through such thick material would have taken significant time and labor. “So, we switched the profile to Shuriken and saved money over an [end plate] joint on the material.”

ATS created a system in the shop to maximize throughput.

“What we did was build a template, so the guys could crank them out,” explains Lee. “I don’t know if you could do it any faster or any cheaper, just because there’s so little labor involved the way that we did it.”

Once the material reached the field, erectors were able to quickly complete the splices and erect the braces. It was the erector’s first time using Shuriken, but the use of standard bolts installed with standard tools minimized the learning curve. According to Lee, that familiarity and the ability to install slip-critical connections is what set Shuriken apart. “This was the only blind option that I was comfortable with,” he said.

By constructing these long braces from Atlas Tube’s Jumbo HSS (the only domestic Jumbo HSS), transporting them on standard flatbeds, and improving connection efficiency using Shuriken, ATS was able to deliver the supports for this monumental bridge on time and on budget. Or as Lee puts it, “My intuition tells me that in almost every scenario, this method would be better, faster, and cheaper.”