Looking for the best HSS on the market? You’ve come to the right place. Our high-quality, American-made HSS steel can help you build beautiful, cost-effective structures that are efficient, sustainable and resilient.

Up to 22" with 1" wall

Up to 28" with 1" wall

Up to 34 x 10” with 1” wall

ASTM A500 and A1085 HSS are cold-formed, welded carbon steel structural tubing products that offer excellent compression and torsional resistance.

ASTM A500, Grade C is the standard specification used in North America and is readily available from North American HSS producers as well as steel service centers.

ASTM A1085 HSS are higher performing and well suited for applications that demand more, such as seismic or bridge applications.

Applications include:

ASTM A500 Resources:

ASTM A1085 Resources:

CSA G40.21 HSS are cold-formed, welded carbon steel structural tubing products produced to the Canadian steel standard. We offer Class C and Class H in accordance with this specification.

Class C HSS are cold-formed and welded similar to ASTM A500 HSS.

Class H HSS are also cold-formed and welded, but then heat-treated in a furnace to stress relieve the product. Class H can be designed to a higher axial capacity in accordance with CSA S16, which may lead to weight savings in column applications.

Resources:

CSA G40 Imperial Section Properties

CSA G40 Metric Section Properties

The largest HSS in North American can help you build bigger, wider and taller than ever before. See how Jumbo HSS are changing the structural steel game.

Not only is steel the strongest building material on Earth, it’s also the greenest. Atlas Tube structural steel includes steel made in electric arc furnaces that emit 75% less CO2 than traditional steelmaking. Each new HSS can contain up to 70% recycled content and is 100% recyclable.

Meet Shuriken — the Better Bolted Connection that’s about to change your building game. Shuriken is a simple yet revolutionary way to field bolt HSS, eliminating the amount of field welds needed, increasing in-shop prefabrication, and saving you time, hassle and money. Go ahead — field bolt HSS like never before!

Find out moreLearn how to incorporate the benefits of HSS into your next project! Work with our expert, Brad Fletcher.

How does the cost of HSS compare to wide flange sections?

HSS is often more expensive than wide flange per pound. However, in many applications, engineers can leverage HSS to achieve the same strength as wide flange while reducing weight as well as finishing and maintenance expenses. In the long run, opting for HSS lowers overall costs. Check out how much you can save on weight and cost with our free HSS vs. Wide Flange Comparison Tool.

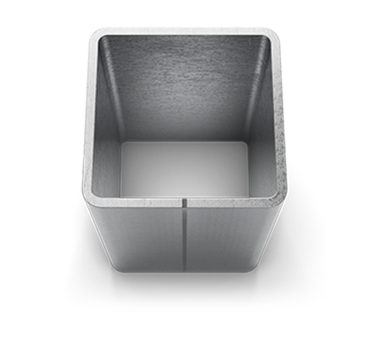

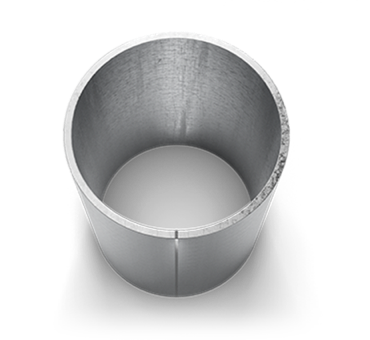

What are the largest HSS sizes available?

Atlas Tube is the ONLY manufacturer in North America offering Made in USA Jumbo HSS. Our largest sizes are:

Is there a way to do field-bolted connections with HSS?

Yes! Traditionally, bolted connections to HSS have required access holes or attachments to the outside of the member. Fortunately, thanks to the Shuriken Structural Nut Keeper from Atlas Tube, many connections such as splices, shear, and moment connections can now be field–bolted. One–sided connectors such as Hollo-Bolt and Blind Bolt can also be useful when designing field-bolted HSS connections.

See what’s available from Atlas Tube’s mills.

View chart